The packaged goods industry faces growing complexity in packaging compliance. Extended Producer Responsibility (EPR) schemes are becoming more dynamic, introducing annual updates and new discount mechanisms. At the same time, the EU Packaging and Packaging Waste Regulation (PPWR) is redefining how packaging must be designed, declared, and reported.

Where most PIM systems stop at listing packaging data, SyncForce provides the foundation for managing both EPR and PPWR compliance, in one connected model.

Two Regulations, Two Perspectives

EPR and PPWR are often discussed together, yet they approach packaging from entirely different angles.

EPR - Extended Producer Responsibility

EPR defines the financial responsibility for packaging once it enters the waste stream. Each country operates its own fee structure and modulation system, such as Verpact in the Netherlands, which introduced recyclability-based discounts of up to €0.60/kg for qualifying plastic packaging.

PPWR - Packaging and Packaging Waste Regulation

PPWR by contrast, defines the design and declaration obligations for packaging placed on the market. From 2026, manufacturers must issue a Declaration of Conformity (DoC) for each Unit of Packaging, covering recyclability, material composition, and substances of concern.

In short:

- PPWR governs what you put on the market.

- EPR governs how it is collected and recycled.

One Product, Multiple EPR Perspectives

A single product can have one PPWR view, yet multiple EPR perspectives.

Take a bottle of ketchup. The PPWR obligation applies to the entire Unit of Packaging, meaning all packaging used for that individual sales unit.

However, EPR fees are calculated per Throw-Away Unit (TAU).

The first TAU is the seal, which is removed and discarded before consumption (general waste). The second TAU consists of the plastic bottle, cap, and front and back labels that consumers discard as plastic waste once the bottle is empty.

This means one product can have several EPR declarations (depending on material combinations and markets) but only one PPWR Declaration of Conformity.

To manage this, brands need packaging data that goes far deeper than just “material type.” They need a granular, hierarchical data model that captures every layer of packaging and its role across the supply chain.

The Foundation: The Golden Hierarchy

At the core of SyncForce is the Golden Hierarchy, a model that mirrors the real world of packaged goods, connecting every packaging element to its commercial and logistical context.

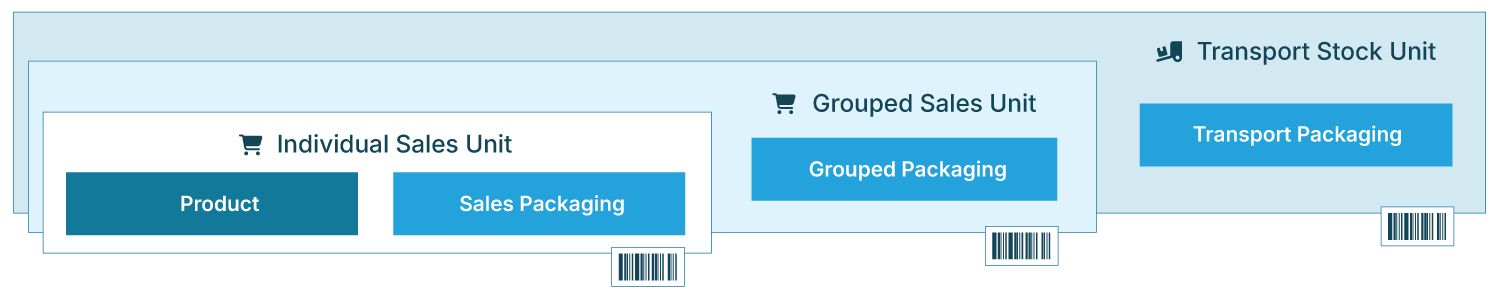

Unlike traditional “Golden Record” PIMs, SyncForce structures data across multiple layers:

Each level contains a detailed packaging specification: from the Unit of Packaging to its Packaging Elements and individual materials. This makes it possible to determine:

- The EPR fee class and modulation per market,

- The PPWR recyclability score and declaration at the packaging system level.

This structure enables manufacturers to manage complex relationships, such as calculating the total EPR fee for a multi-product floor display across markets like NL and BE, something mainstream PIMs were never designed to handle.

Built-In Readiness for EPR and PPWR

SyncForce already supports the essential data layers for both regulatory frameworks:

- Packaging Element Level: Material type, form (rigid or flexible), weight, material class, and composite structure.

- Composite Material Level: Detailed breakdown of multi-layer materials such as PET, EVOH, or PE, essential for EPR fee modulation.

- Supply Chain Level: Full hierarchy from Sales Unit to Transport Unit, allowing declarations per target market and country of sale.

Together, these components make SyncForce the most advanced foundation for managing the interplay between EPR cost modelling and PPWR design conformity.

Turning Compliance into Insight

With SyncForce, packaging data becomes a tool for foresight, not just reporting.

You can:

- Simulate next-year EPR cost impact per country or market, based on projected fee tables.

- Forecast PPWR recyclability performance, identifying improvement opportunities before design freeze.

- Generate annual reports by combining trade flow and shipment data per market automatically.

This integration allows organisations to move from reactive compliance to proactive design and financial planning.

What Comes Next

SyncForce’s foundation is already prepared for Verpact-style EPR fee modulation and PPWR packaging hierarchy management. The next steps are driven by the ongoing PPWR implementation roadmap:

- Contact Sensitivity Classification for PCR eligibility (for example 10% versus 20% thresholds).

- Barrier Layer Modelling for recyclability and design-for-recycling scoring.

- Disposal Unit Level Modelling, including Throw-Away Units (TAUs) and Deposit-Return Units (DRUs) for national EPR and DRS reporting.

- Declaration of Conformity Automation, powered by the SyncForce Publishing Robot, which will automatically generate DoCs like the 2028 PPWR Sales Unit Template.

- Recyclability Score Calculation, once the EU publishes the official methodology (expected around 2028).

SyncForce is developing these extensions in collaboration with HEINEKEN, Ardagh, Smurfit Westrock, Ahold, and GS1 through a joint PPWR workgroup. This ensures that the resulting system is aligned with both regulatory requirements and the practical needs of real-world packaging supply chains.

Final Thought

The combination of EPR and PPWR is reshaping how manufacturers think about packaging, not only as a cost factor but as a strategic asset. Managing both requires a system that sees packaging as a structured hierarchy, not a field in a spreadsheet.

That is why SyncForce Circular PIM offers the best foundation for EPR and PPWR today, and the most future-ready platform for the requirements still to come.