In the dynamic world of packaged goods manufacturing, the traditional Linear PIM approach often falls short of meeting the complex demands of product lifecycle management. SyncForce champions a Circular PIM model, which is more aligned with the sustainable business needs of manufacturers. This model excels in areas where Linear PIM systems, which are usually designed for retail and wholesale, do not naturally fit.

(This article was previously posted on LinkedIn by Hans de Gier.)

The Linear PIM process, as supported by most eCommerce PIM systems, has three core functions:

While this is great for wholesale and retail, it does not fit the way of working within packaging goods manufacturing. Unlike Linear PIM systems that focus on onboarding as a principal feature—assuming products are ready to sell and merely need to be added to the system—Circular PIM acknowledges that the commercial life of a product begins much earlier.

Let’s explore the distinctions between these systems and understand why a Circular PIM is essential for today’s manufacturers.

Adaptive Change Management vs. Onboarding

Linear PIM systems emphasize onboarding. They assume that products are ready to sell and just need adding to the system. Yet, in the world of manufacturing, the commercial life of a product starts earlier. It starts with any change in the portfolio change. This can include adjustments in product formulas, the introduction of new technologies or packaging adjustments, such as a new bottle design that contains more recycled content.

These changes often affect multiple products and shipping units, such as cases, displays, and trays, and require collaborative efforts from various teams. Circular PIM’s strength lies in integrating adaptive change management capabilities—planning, workflow, and artwork approval—directly into the product information management process, enhancing flexibility and responsiveness across the product lifecycle.

Capture at the Source vs. Enrichment

In a Linear PIM setup, the core product data is typically provided by the brand, and retailers may add extra details or tweak descriptions to better target their audience. However, in packaged goods manufacturing, the product data evolves incrementally throughout the different stages of the go-to-market process.

Circular PIM harnesses these nuances through its “capture at the source” capability, where the digital product profile is built step-by-step in alignment with the development of the actual product. This ensures that the captured data is accurate and complete, fully reflecting the product’s attributes by the time it is ready to be launched.

Seamless Data Distribution vs. Publication

Retail-focused Linear PIM systems are usually designed around an omni-channel strategy. Once a product is finalized, it needs to be consistently published across all sales channels. In contrast, manufacturing demands a more nuanced multi-channel strategy. Products may be listed differently, at different times, across various channels depending on strategic business needs.

Circular PIM accommodates this diversity with its “Seamless Data Distribution” feature, ensuring that product information is effectively tailored and timed perfectly across all channels for maximum impact.

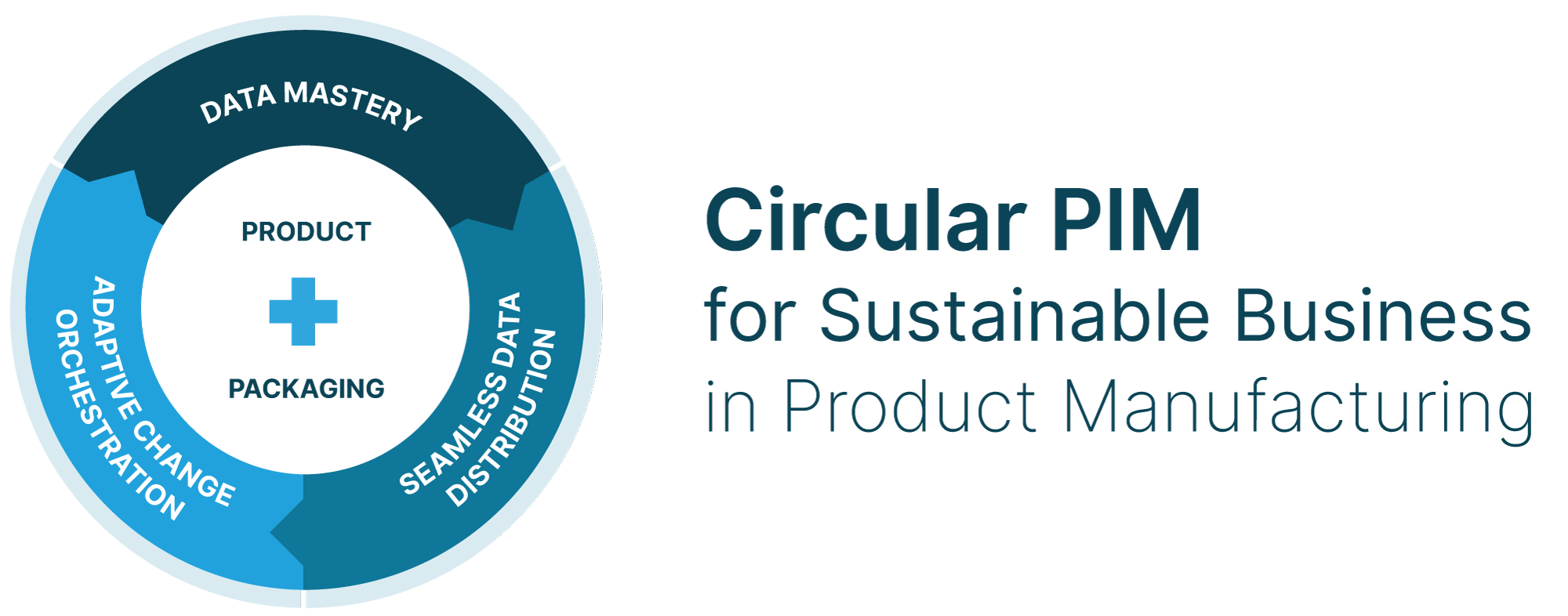

Circular PIM: The Core Pillars

The three pillars of Circular PIM:

serve as the foundation of SyncForce’s approach to PIM. These pillars are designed to empower FMCGs/CPGs to manage product and packaging data more effectively, ensuring sustainability and adaptability in a competitive market.